Brass Cocks and Valves

Brass Cocks and Valves Specification

- Valve Size

- 1/8 to 2

- Features

- Corrosion Resistant, Leak Proof, Durable, Precision Machined Body

- Connection Type

- Threaded (BSP/NPT)

- Valve Type

- Ball Valve, Gate Valve, Check Valve, Bib Cock

- Control System

- Manual Handle / Knob

- Application

- Plumbing, Industrial, Gas Fitting, Water Supply, Oil, Steam

- Sealing

- PTFE / Neoprene / NBR / Rubber Seal

- Structure

- Ball, Globe, Gate, Check, Angle, Bib Cock

- Type

- Cocks and Valves

- Power

- Manual

- Pressure

- Upto 16 Bar

- Media

- Water, Oil, Gas, Steam, Air

- Port Size

- 1/8 to 2 (BSP/NPT Threaded)

- Temperature

- Upto 120C

- Disc

- Brass / Forged Brass

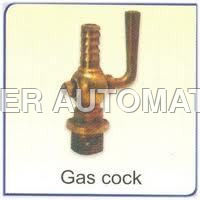

About Brass Cocks and Valves

Brass Cocks & Valves

We provide our clients with array of dimensionally accurate Brass Cocks & Valves that is made from high grade of brass. Complying with highest standards of quality, these brass radiator air cocks are robustly constructed in standard and customized forms. Offered in all sizes and varied specifications, these air cocks are offered in standard and customized specifications, as per definite needs of our clients.

- Brass Groves Banjo No. 1

- Brass Groves Banjo No. 2

- Pet Cock Size 1/4" B.S.P.

- Pet Cock Size 3/8"

- Pet Cock Size 1/2"

- Drain Cock with nut Nipple Size 1/4" B.S.P.

- Drain Cock with nut Nipple Size 3/8"

- Drain Cock with nut Nipple Size 1/2"

- Drain Cock without nut Nipple Size 1/4x1/4

- Drain Cock without nut Nipple Size 3/8x3/8

- Drain Cock without nut Nipple Size 1/2x1/2

- Syphen Cock C.P. Size 1/4" B.S.P.

- Syphen Cock C.P. Size 3/8" B.S.P.

- Syphen Cock C.P. Size 1/2" B.S.P.

FAQs of Brass Cocks and Valves:

Precision-Engineered for Multiple Applications

These brass cocks and valves are specifically designed for versatile usage in various sectors such as plumbing, gas fittings, industrial installations, and water supply systems. Their robust construction ensures maximum reliability across demanding environments and media, including water, oil, steam, gas, and air.

Superior Sealing and Leak Prevention

Featuring advanced sealing technology with PTFE, neoprene, NBR, or rubber, our valves guarantee leak-proof performance and long-term corrosion resistance. This makes them an excellent choice for installations requiring reduced maintenance and consistent operational integrity.

Manual Control for Greater Flexibility

Equipped with manual handles or knobs, these valves allow precise control over the flow of media. The threaded BSP/NPT connections facilitate easy installation and replacement, ensuring compatibility with a wide range of system requirements and enhancing operational flexibility.

FAQ's of Brass Cocks and Valves:

Q: How do brass cocks and valves enhance system reliability in industrial and plumbing applications?

A: Brass cocks and valves provide corrosion resistance and leak-proof operation due to precision machining and high-quality sealing materials (PTFE, neoprene, NBR, rubber). Their durability and robust construction minimize downtime and maintenance requirements, ensuring reliability in critical applications.Q: What types of sealing materials are used in these valves, and what are the benefits?

A: The valves use PTFE, neoprene, NBR, or rubber seals. These materials provide excellent chemical resistance, prevent leaks, and enhance durability, making the valves suitable for water, oil, gas, steam, and air applications.Q: Where can these brass cocks and valves be installed?

A: They are suitable for installations in plumbing systems, industrial plants, gas fittings, oil pipelines, water supply networks, and steam systems. Their wide range of types and threaded (BSP/NPT) connections support diverse applications in residential, commercial, and industrial settings.Q: When should I choose manual-operated brass valves for my project?

A: Manual brass valves are ideal when precise flow regulation is required, and automation is not necessary. Their simple operation with handles or knobs makes them suitable for infrastructure where manual monitoring and control are preferred, such as gas, water, and oil distribution systems.Q: What is the process of installing these valves with BSP/NPT threads?

A: Installation involves selecting the appropriate valve size and type, applying thread sealant to the BSP or NPT ends, and tightening the valve onto the pipe using the manual handle or knob. Compatibility with standard threaded connections ensures straightforward integration into existing pipelines.Q: How do these valves withstand high pressures and temperatures?

A: Constructed from durable forged brass and equipped with resilient seals, the valves handle pressures up to 16 bar and temperatures up to 120C. This robust design makes them suitable for demanding industrial and utility service conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Cocks Category

657 snuber

Pressure : Other, 0.5 Bar to 10 Bar

Material : Brass

Port Size : 1/4 To 2

Disc : Stainless Steel

Control System : Electric

Connection Type : Threaded

Stainless Steel Bend Nose Cock

Pressure : Other, Standard water pressure (up to 10 bar)

Material : Stainless Steel

Port Size : 15mm (1/2 inch)

Disc : Stainless steel

Control System : Rotary lever handle

Connection Type : Male threaded end

s.s. cock

Pressure : Other, 10 bar maximum

Material : Stainless Steel 304/316

Port Size : 1/4 inch to 2 inch

Disc : Stainless Steel

Control System : Manual

Connection Type : Threaded End, BSP/NPT

SS Gas Cock

Pressure : Other, Maximum working pressure up to 10 bar

Material : Body: SS304/SS316

Port Size : 1/4 inch BSP or as specified

Disc : Robust stainless steel disc

Control System : Manual

Connection Type : BSP threaded connection

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry