Hydro Pneumatic Cylinder

Hydro Pneumatic Cylinder Specification

- Media

- Filtered Compressed Air and Hydraulic Oil

- Speed

- Up to 400 mm/sec

- Maximum Torque

- High force output up to 10 tons depending on model

- Application

- Suitable for Pressing, Clamping, Riveting, and Punching

- Operating Pressure

- 2 to 8 bar (air); 20 to 250 bar (hydraulic)

- Cylinder Bore Size

- Available from 25 mm to 200 mm

- Working Medium

- ISO VG32 Hydraulic Oil and Dry Air

- Stroke Length

- Customizable from 20 mm to 500 mm

- Mounting Type

- Flange, Foot, Rear Clevis, or Custom

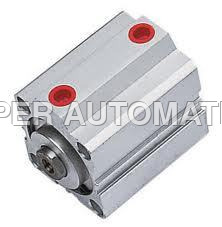

About Hydro Pneumatic Cylinder

We are well-acclaimed as one of the noteworthy manufacturers, suppliers and exporters of an optimum quality Hydro Pneumatic Cylinder. Featured with a magnetic piston, our cylinder is ideally used for manual control of air flow pressure. To cater to our clients demands, we offer this cylinder in varied designs, patterns and specifications. Offered product undergoes stringent quality testing with our in-house testing facilities before final outing from our end. Hydro Pneumatic Cylinder, we offer is invariably known for the following significant attributes:

- Rugged construction

- Corrosion resistance

- Easy handling & portability

- Environment friendly nature

Other details:

Available in 25 bore x 25 to 1000mm stroke length

Versatile and Customizable Design

The hydro pneumatic cylinder is engineered for adaptability, featuring customizable stroke lengths and diverse mounting types including flange, foot, or rear clevis. With bore sizes from 25 mm up to 200 mm, this cylinder can be tailored to meet specific industrial application needs, whether in pressing, clamping, or specialized tasks.

High Force Output and Efficient Performance

Capable of delivering up to 10 tons of force, the cylinder operates smoothly with both filtered compressed air and hydraulic oil. Its maximum speed reaches 400 mm/sec, offering rapid action for demanding production lines in various sectors, while maintaining reliability and efficient energy use.

Trusted Supply Across India

Available through an established network of Indian distributors, exporters, suppliers, and traders, our hydro pneumatic cylinders come with knowledgeable support and accessible after-sales service. This ensures clients receive both dependable products and the guidance needed for optimal integration into their manufacturing systems.

FAQs of Hydro Pneumatic Cylinder:

Q: How does a hydro pneumatic cylinder operate in industrial applications?

A: A hydro pneumatic cylinder utilizes compressed air for the initial movement and hydraulic oil for generating high force, allowing precise, powerful control during pressing, clamping, riveting, or punching operations.Q: What are the customization options for stroke length and mounting types?

A: Stroke lengths can be tailored between 20 mm and 500 mm, while mounting options include flange, foot, rear clevis, or custom types to suit specific installation requirements.Q: When should I consider using a hydro pneumatic cylinder over other actuators?

A: You should choose a hydro pneumatic cylinder when you need high force output (up to 10 tons) combined with adjustable speed and versatility, especially in applications like punching, pressing, or clamping.Q: Where can these cylinders be installed within a manufacturing process?

A: These cylinders are suited for installation in automated production lines, assembly stations, or specialized machinery where efficient linear motion and high force are paramount.Q: What is the recommended working medium and pressure for optimal performance?

A: Optimal performance is achieved using ISO VG32 hydraulic oil and dry, filtered compressed air, working at 28 bar for pneumatic and 20250 bar for hydraulic operations.Q: How can users benefit from choosing this cylinder in their facility?

A: Users benefit through reliable high-force performance, customizable integration, reduced maintenance requirements, and increased productivity in tasks that demand repeatable precision and speed.Q: What is the process for selecting the right cylinder configuration?

A: To select the right configuration, users should consider application-specific requirements such as desired force output, stroke length, bore size, mounting type, and compatibility with available working media.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pneumatic Cylinder Category

TC CYLINDER MOUNTING

Material : Stainless Steel

Power : Pneumatic

Structure : Cylinder Mounting

Media : Air

Air Consumption : Standard

Speed : Normal

FA CYLINDER MOUNTING

Material : Mild Steel

Power : Manual/Mechanical

Structure : Flange Type Mounting

Media : Air

Air Consumption : Low

Speed : Standard

C2Q CYLINDER

Material : Aluminium Alloy

Power : Pneumatic

Structure : Double Acting Cylinder

Media : Filtered Compressed Air

Air Consumption : Low

Speed : High Speed Operation

SC DOUBLE ENDED PNEUMATIC CYLINDER

Material : Aluminum alloy (cylinder tube), stainless steel (piston rod), nitrile rubber (seals)

Power : Pneumatic (operates using compressed air, not electric)

Structure : Double ended piston rod; tie rod type design

Media : Filtered compressed air

Air Consumption : Depends on bore, stroke and operating pressure; typically specified in L/min at specified conditions

Speed : 50 to 800 mm/sec (variable based on load and air supply)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry