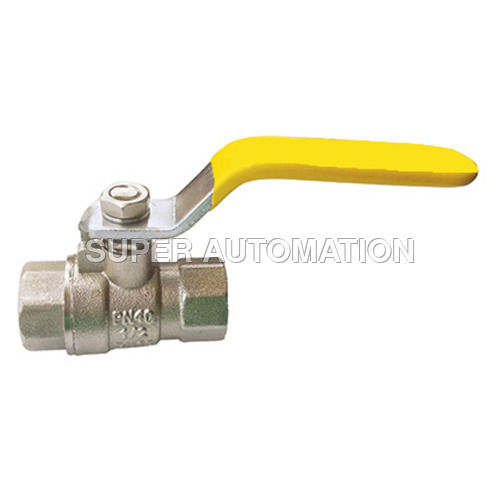

IC Ball Valve

IC Ball Valve Specification

- Features

- Corrosion Resistance, Smooth Operation, Leak Proof

- Valve Size

- 1/2 to 4 (15mm to 100mm)

- Material

- Cast Iron Body, Stainless Steel Ball

- Connection Type

- Screwed Ends / Flanged Ends

- Control System

- Manual Lever Operated

- Valve Type

- Ball Valve

- Sealing

- PTFE

- Structure

- One Piece/Two Piece/Three Piece

- Application

- Water, Oil, Gas Flow Control

- Type

- IC Ball Valve

- Power

- Manual

- Pressure

- PN16

- Media

- Water, Oil, Gas

- Port Size

- 15mm to 100mm

- Disc

- Stainless Steel or Brass

- Pin

- Single/Double

- Handle Material

- Steel with PVC Sleeve

- Testing Standard

- EN 12266

- Working Life

- Up to 1 Million Cycles

- Mounting Position

- Any Direction

- Flow Characteristic

- Full Bore

- Applicable Industries

- Water Treatment, Chemical, Industrial, Agriculture

- Body Coating

- Epoxy Painted

- End Connection Standard

- BSP / ANSI / DIN

- Internal Surface Finish

- Machined

About IC Ball Valve

With the aid of our knowledgeable workforce, we are able to manufacture, supply and export IC Ball Valve. This valve is manufactured at our unit using premium stainless steel which is procured at our end from the authentic vendors of the market. Our offered product is used extensively in various industries and manufacturing units for opening and closing the inlet of pipes. In order to provide international standards to this IC Ball Valve, we make these with the aid of advanced technology and latest machines.

Features:

-

Smooth functioning

-

No need for lubrication

-

Low maintenance

-

Fine finishing

Long-Lasting Construction

Crafted with a durable cast iron body, stainless steel ball, and epoxy coating, the IC Ball Valve delivers corrosion resistance and extended service life even in harsh environments. Its internal machining ensures a precise fit for smooth operation cycle after cycle.

Versatile Applications

Designed for manual control of water, oil, or gas flow, this versatile valve fits seamlessly into a variety of settings: from water treatment plants to industrial pipelines and agricultural irrigation systems. Multiple sizes and connection types enhance adaptability for different installation requirements.

Reliable, Full Bore Performance

The full bore structure of the IC Ball Valve provides unrestricted flow, minimizing pressure drop and ensuring efficient fluid transfer. Stringent EN 12266 testing and PTFE sealing establish its leak-proof reliability across various media and conditions.

FAQs of IC Ball Valve:

Q: How do I install the IC Ball Valve for optimal performance?

A: Installation is straightforward due to the valves design, which allows mounting in any direction. Choose the suitable end connection (screwed or flanged) per your pipeline standard (BSP, ANSI, or DIN). Secure the valve, ensuring proper alignment and leak-proof connections for optimal operation.Q: What maintenance is required to ensure long working life of the valve?

A: Thanks to its corrosion-resistant materials and precision machining, the valve requires minimal maintenance. Periodic inspections to check for wear on the PTFE seals and handle operation are recommended. Clean the external surfaces as needed to preserve the epoxy coating.Q: When should I opt for a full bore IC Ball Valve over other types?

A: A full bore ball valve is ideal when minimizing flow restriction is essential. Its recommended for processes requiring high flow rates and minimal pressure drops, such as water treatment or large fluid transfer lines.Q: Where can this IC Ball Valve be used effectively?

A: The IC Ball Valve is suited for installations in water treatment facilities, chemical plants, industrial pipelines, agricultural irrigation systems, and oil or gas transfer lines. Its robust construction and versatile features allow application across various sectors.Q: What is the process for selecting the right port size and connection type?

A: First, determine your pipelines size and compatibility with BSP, ANSI, or DIN standards. Select a port size between 15mm and 100mm that matches your flow requirements, and choose either screwed or flanged ends to fit the existing system.Q: What are the benefits of using a manually operated IC Ball Valve?

A: Manual operation offers precise on/off control, simple installation, and low maintenance demands. The lever with a PVC sleeve ensures a comfortable grip, while the valves leak-proof design and robust materials provide reliable, long-term service.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valves Category

V408 Solenoid Valve

Price 1000 INR / Piece

Minimum Order Quantity : 5 Pieces

Control System : Electromagnetic

Power : Other, AC/DC, typically 6W to 12W

Port Size : 1/2 inch (15 mm)

Application : Industrial and Commercial Automation

BRASS BALL VALVE

Price 500 INR / Piece

Minimum Order Quantity : 5 Pieces

Control System : Manual

Power : Other, Not Applicable (Manual Operation)

Port Size : Standard

Application : General Plumbing Water Flow Control

WATER SOLENOID

Price 1000 INR / Piece

Minimum Order Quantity : 5 Pieces

Control System : Electromagnetic

Power : Other, 15W

Port Size : 1/2 inch

Application : Water flow control

Plastic and Metal Solenoid Valve Coil

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Not Provided

Power : Other, Not Provided

Port Size : Not Provided

Application : Solenoid Valve Coil

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry