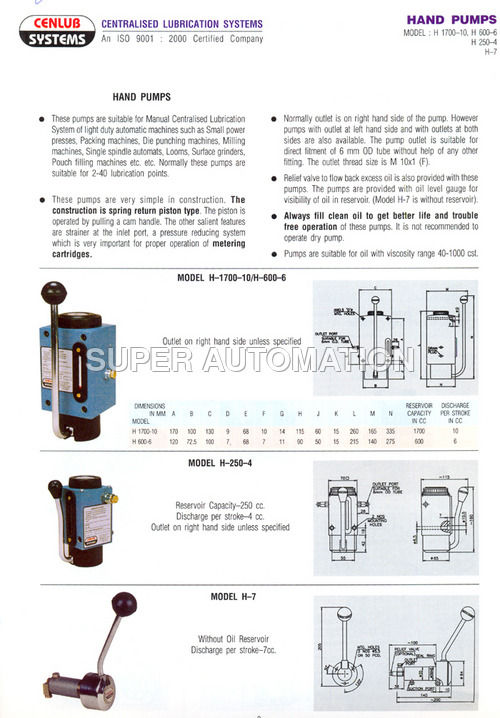

Lubrication Hand Pump

Price 2800 INR/ Piece

Lubrication Hand Pump Specification

- Capacity

- 500 cc

- Material

- Aluminium/Steel Body

- Automatic Grade

- Manual

- Size

- Standard

- Type

- Manual Hand Operated Lubrication Pump

- Grade

- Industrial

- Dimension (L*W*H)

- Approx. 220 x 110 x 160 mm

- Noise Level

- Silent Operation

- Power

- Manual/Hand Operated

- Weight

- Around 2 kg

- Sealing

- Oil Resistant Nitrile Seals

- Mounting Type

- Tank Top Mounted

- Piston Material

- Hardened Steel

- Operating Pressure

- Up to 12 kg/cm²

- Finish

- Corrosion Resistant Powder Coating

- Reservoir Material

- Transparent Acrylic or Metal

- Pump Outlet

- 1/4 inch BSP

Lubrication Hand Pump Trade Information

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 1 Week

About Lubrication Hand Pump

Owing to our vast and thorough experience in this domain, we gave been able to manufacture and supply Lubrication Hand Pump. These pumps are widely utilized in MCL systems. Easy to install, our offered pumps are highly demanded in the market. In addition to this, our belts are made using hi-tech machinery & sophisticated tools. We also ensure to make these pumps available to the clients at the best market price. Our made Lubrication Hand Pump is also widely used for die punching, milling, single spindle machine fabrication and many other applications.

Features:

- Accurate mesh shape

- Compact size

- Low noise level

- Oil & corrosion resistant

Sturdy and Practical Construction

With a durable aluminium or steel body and a corrosion-resistant powder-coated finish, this lubrication pump is built to handle tough industrial conditions. The use of premium materials like hardened steel for the piston and oil-resistant nitrile for the seals ensures longevity and reliable performance, even under demanding use.

Efficient Manual Lubrication

Designed for manual operation, this pump delivers up to 12 kg/cm of pressure, making it suitable for diverse lubrication tasks. The standard 1/4 inch BSP pump outlet and tank top mounting facilitate easy integration, while the transparent acrylic or metal reservoir allows for quick monitoring and refilling of lubricants.

FAQs of Lubrication Hand Pump:

Q: How is the manual lubrication hand pump operated?

A: The pump is operated manually using a hand lever. By moving the lever, pressure is built and lubricant is dispensed through the 1/4 inch BSP outlet to the connected machinery components.Q: What types of lubrication systems is this pump suitable for?

A: This hand-operated pump is ideal for use in industrial lubrication systems requiring precise, controlled lubrication, such as milling, packaging, or textile machinery. Its standard size and mounting make it adaptable to most equipment.Q: When should the lubricant reservoir be refilled?

A: The reservoir, with a 500 cc capacity, should be refilled when the lubricant level becomes low, as observed through the transparent acrylic option, or at regular maintenance intervals to ensure consistent operation.Q: Where is the pump typically installed on equipment?

A: It is designed for tank top mounting, meaning it is installed directly on top of the equipments lubricant tank, ensuring secure placement and convenient access for operators.Q: What is the benefit of using a transparent acrylic reservoir?

A: A transparent acrylic reservoir allows operators to easily monitor lubricant levels, preventing dry running and facilitating timely refills, which helps maintain smooth and uninterrupted equipment function.Q: How does the pump ensure reliable sealing and prevent leaks?

A: The pump utilizes oil-resistant nitrile seals, which effectively prevent leaks even under high pressure and frequent use, thus maintaining the purity and effectiveness of the lubricant supplied.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil Lubrication Products Category

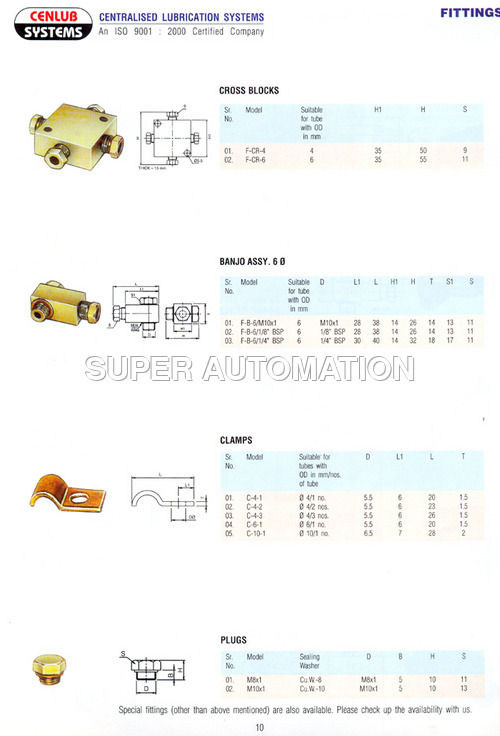

Oil Lubrication Fittings

Material : Brass / Steel / Stainless Steel

Size : 1/8, 1/4, 3/8, 1/2 (Varies according to fitting)

Grade : Industrial

Type : Other, Oil Lubrication Fittings

Usage & Applications : Used in lubrication systems for oil distribution in industrial machinery and automotive equipment

Dimension (L*W*H) : As per requirement

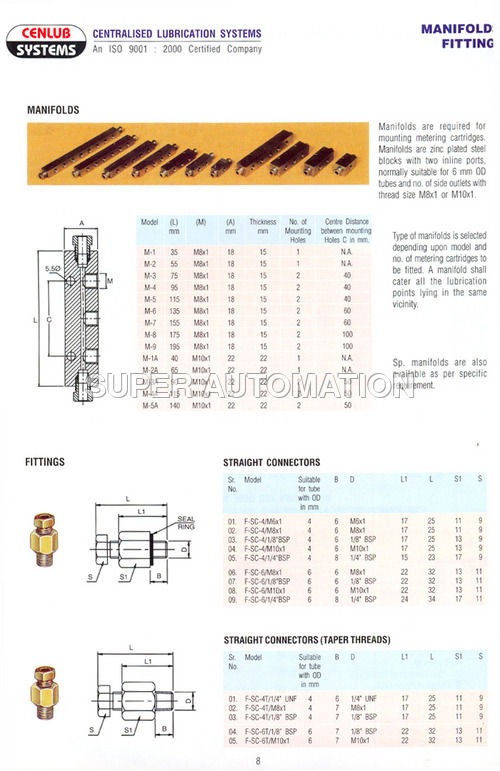

Brass Manifold Fitting

Material : Brass

Size : 1/2 inch, 3/4 inch, or specified

Grade : Industrial

Type : Other, Manifold Fitting

Usage & Applications : HVAC systems, heating systems, water & gas distribution, industrial automation

Dimension (L*W*H) : Custom/Standard as per model

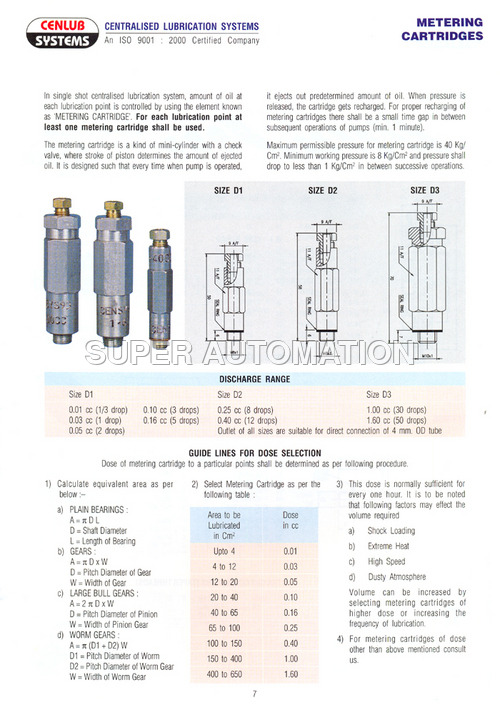

Metering Cartridge

Material : Metal

Size : As required

Grade : Industrial

Type : Other, Metering Cartridge

Usage & Applications : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry