Pressure Gauges

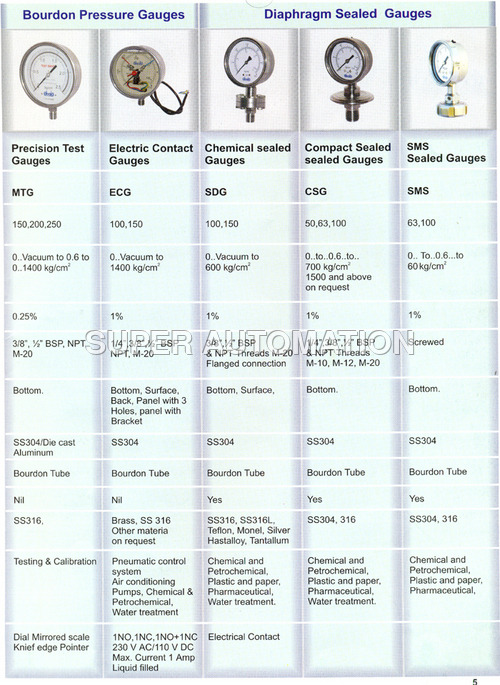

Pressure Gauges Specification

- Connectivity Type

- Threaded Connection (BSP/NPT)

- Efficiency

- High accuracy, 1.6% FSD

- Mounting Type

- Bottom / Back Flange or Panel Mount

- Operating Pressure

- Up to 1000 Bar

- Accessories

- Rubber Gasket, Mounting Brackets

- Application

- Hydraulic Systems, Pneumatics, Process Industries, Gas and Liquid Measurement

- Power Source

- Mechanical

- Sealing Type

- Hermetically Sealed Case

- Body Material

- Stainless Steel / Brass / Mild Steel

- Structure

- Bourdon Tube Type

About Pressure Gauges

Having attained vast industry experience in this domain, we have mustered up in manufacturing, supplying and exporting a broad range of Pressure Gauges. Designed with utmost precision, our device is widely used for measuring the pressure of a liquid or gaseous material. Offered products find their applications in automobile, aviation, chemical, pharmaceutical and food & beverage industries. The Pressure Gauges, we offer are well-acclaimed by the clients for the below enlisted features:

-

Compact design

-

Lightweight

-

Portability

-

Longer service life

-

Accurate readout

Versatile and Durable Construction

Built for durability, these pressure gauges utilize high-quality materials such as stainless steel, brass, or mild steel, ensuring reliable performance in demanding environments. The IP65-rated enclosure offers robust protection, while a hermetically sealed case prevents ingress of dust and moisture, making them ideal for both indoor and outdoor industrial applications.

Precision Measurement Across Applications

With accuracy classes of 1.6% or 2.5% per EN 837 standards, these Bourdon tube gauges deliver dependable precision for hydraulic systems, pneumatics, process industries, and the measurement of gases and liquids. Custom range capabilitiesfrom vacuum to 1000 barallow optimal configuration based on specific operational requirements.

Flexible Mounting and Easy Integration

These gauges can be mounted using bottom, back flange, or panel mounts, and they fit 1/4" or 1/2" BSP or NPT threaded connections. Accessories such as rubber gaskets and mounting brackets facilitate seamless installation, providing users with hassle-free setup and integration into both new and existing systems.

FAQs of Pressure Gauges:

Q: How do I select the correct dial size and range for my application?

A: To choose the right dial size, consider your applications space and visibility requirements. The available sizes63 mm, 100 mm, and 150 mmoffer flexibility for different installation spaces. Select the custom-measurement range according to your process needs, from vacuum up to 1000 bar, to ensure accurate readings.Q: What are the benefits of an IP65-rated case and hermetically sealed design?

A: An IP65-rated case protects the gauge from dust and water jets, extending its lifespan in challenging environments. The hermetically sealed case enhances protection against moisture and contaminants, thereby preserving the instruments accuracy and reducing maintenance needs.Q: Where can these pressure gauges be used effectively?

A: These gauges are suited for hydraulic systems, pneumatic equipment, process industries, and general gas or liquid pressure measurement. They perform reliably in both indoor and outdoor settings, especially where high durability and protection against the elements are required.Q: What connection and mounting options are available for installation?

A: You can choose between 1/4" or 1/2" BSP or NPT threaded connections for easy plumbing integration. Installation options include bottom or back flange, and panel mounting to suit varied layout and accessibility requirements. Accessories like mounting brackets and gaskets are also available.Q: How does the gauge ensure accurate pressure measurement?

A: These gauges utilize a Bourdon tube mechanism and offer accuracy classes of 1.6% FSD or 2.5% per EN 837 standard. The precision design, together with quality materials and customizable pressure ranges, ensures measurement reliability in critical applications.Q: What materials and movements are used, and why do they matter?

A: The gauges are constructed from stainless steel, brass, or mild steel, with movement parts in brass or stainless steel. These materials offer resistance to corrosion and mechanical stress, improving the instruments durability and ensuring consistent performance in varied industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Gauges Category

wika pressure guage

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Body Material : Other, Stainless Steel / Brass

Sealing Type : Other, Gasket/ORing

Accessories : Protective Rubber Cover, Snubber, Flange

Application : Hydraulic, Pneumatic, Chemical, Petrochemical Industries

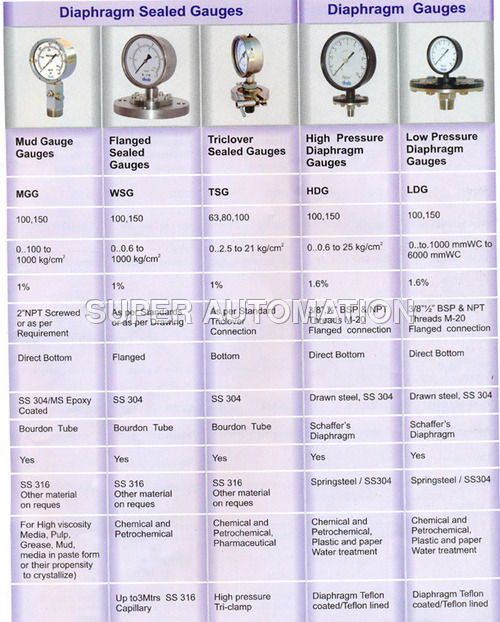

Diaphragm Sealed Gauges

Price 1450 INR / Piece

Minimum Order Quantity : as per requirement Piece

Body Material : Other, SS304 / SS316 Stainless Steel

Sealing Type : Other, Diaphragm Welded

Accessories : Capillary, Flange, Syphon, Vent Plug

Application : Chemical Industry, Food & Pharma, Petrochemical, Process Plants

Flanged Sealed Gauges

Body Material : Other, Stainless Steel / Brass

Sealing Type : Other, Diaphragm / Gasket Sealed

Accessories : Mounting Flange, Installation Bolts

Application : Chemical, Petrochemical, Water Treatment, Process Industry

Stainless Steel Pressure Gauge

Body Material : Stainless Steel

Sealing Type : Other, Gasket Sealed

Accessories : Protective Cover, Mounting Fittings

Application : Industrial Process Monitoring, Hydraulic Systems, Chemical Processing, Water Treatment Plants

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry