SS Butterfly Valve

SS Butterfly Valve Specification

- Valve Size

- 1.5 to 12 (DN40 to DN300)

- Valve Type

- Butterfly

- Connection Type

- Wafer / Lugged

- Features

- Corrosion Resistant, Easy Operation, Leak Proof

- Material

- Stainless Steel SS304 / SS316

- Control System

- Manual Lever / Gear Operated

- Application

- Industrial, Water Treatment, Chemical Processing

- Sealing

- EPDM / PTFE / NBR

- Structure

- Butterfly

- Type

- Wafer Type

- Power

- Manual

- Pressure

- PN10 / PN16

- Media

- Water, Oil, Gas, Chemical

- Port Size

- Standard

- Disc

- Stainless Steel

- Pin

- Stainless Steel

- Design Standard

- API 609 / EN 593

- Body Material

- Stainless Steel

- Surface Finish

- Polished

- End Connection

- Wafer / Lug

- Actuation Options

- Manual, Pneumatic, Electric (On Request)

- Application Area

- HVAC, Food & Beverage, Marine, Fire Fighting

- Test Pressure

- Hydrostatic

- Operation

- Quarter Turn (90°)

- Mounting

- ISO 5211 Pad

- Face to Face Standard

- EN558

- Working Mediums

- Liquids, Gases, Slurries

- Seat Material

- EPDM, NBR, PTFE, Silicon

- Stem Material

- Stainless Steel

- Handle Type

- Lever / Gearbox

About SS Butterfly Valve

We are engaged in manufacturing, supplying and exporting SS Butterfly Valve.This valve is manufactured under the supervision of our trained professionals using premium raw materials which are obtained at our end from the authentic vendors of the market. Our offered product is suitable to be used in various industries for installing in various machines. This valve is packed with premium packaging materials in order to provide safe transportation at our clients place. Our SS Butterfly Valve is available in various sizes and dimensions in order to meet with the differential needs of our customers.

Features:

-

Smooth functioning

-

Corrosion resistant

-

Seamless finish

-

Perfect dimensions

Precision Engineering and Material Excellence

Manufactured from high-grade stainless steel (SS304/SS316), this butterfly valve offers superior resistance to corrosion and mechanical wear, even in aggressive environments. The highly polished surface finish adds an extra layer of protection, making it suitable for applications requiring cleanliness and durability. Whether you require valves for water, oil, gas, or chemical transfer, this reliable construction ensures longevity and safety.

Versatile Operation and Installation

Designed for easy integration, the valve features both wafer and lug connection types as per EN558 standards. Operated with a quarter-turn (90), the unit is available with manual lever, gear, and optional pneumatic or electric actuators for versatile control. The ISO 5211 mounting pad allows for straightforward actuator installation, making the valve highly adaptable to automation in industrial and commercial systems.

Leak-Proof Sealing and Reliable Performance

Choose from EPDM, NBR, PTFE, or Silicon seats to best match your applications media and requirements. The hydrostatic test pressure rating assures leak-proof integrity even under rigorous operating conditions. The valves robust internal and external design meets stringent industry standards, guaranteeing dependable performance for water treatment, chemical processing, HVAC, and more.

FAQs of SS Butterfly Valve:

Q: How does the SS Butterfly Valve operate and what does quarter-turn actuation mean?

A: The SS Butterfly Valve operates using a quarter-turn (90) actuation, meaning the handle or gearbox needs only to be rotated 90 degrees to fully open or close the valve, enabling quick and efficient flow control. This mechanism is suitable for rapid shut-off or flow regulation in various media including liquids, gases, and slurries.Q: What seat materials are available and how do I select the appropriate one for my application?

A: Seat materials include EPDM, NBR, PTFE, and Silicon, each suited for different applications. EPDM is ideal for water and mild chemicals, NBR for oils and hydrocarbons, PTFE for aggressive chemicals, and Silicon for higher temperatures. Selecting the right seat ensures compatibility with your process media and service conditions.Q: When should I consider using the lever versus the gearbox or actuator for the SS Butterfly Valve?

A: A lever handle is suitable for manual operation in smaller valve sizes or where quick manual shut-off is required. A gearbox is recommended for larger valves or where additional torque is needed for easier operation. For automated control or remote operation, optional pneumatic or electric actuators can be fitted upon request.Q: Where can the SS Butterfly Valve be installed and what application areas is it best suited for?

A: The valve is designed for installation in various pipeline systems using either wafer or lug ends, conforming to EN558 face-to-face standards. It is suitable for industrial applications including HVAC, food & beverage processing, marine systems, fire fighting, water treatment, chemical processing, and power plants.Q: What is the process for testing and ensuring the valve is leak proof?

A: The SS Butterfly Valve undergoes a hydrostatic pressure test as per industry standards to verify its leak-proof integrity. This process involves subjecting the valve to specified internal pressures to ensure there is no leakage from the body or seat seals before being approved for dispatch.Q: How does the stainless steel construction benefit my operations?

A: Stainless steel (SS304/SS316) provides exceptional corrosion resistance, a polished hygienic surface, and mechanical strength. This makes the valve ideal for aggressive or sanitary environments, reducing maintenance needs and extending service life, which translates to lower total cost of ownership.Q: What are the advantages of using a butterfly valve over other valve types in industrial settings?

A: Butterfly valves offer compact dimensions, lighter weight, lower cost, and quick operation compared to gate or globe valves. Their design is well-suited for large-diameter pipes and various actuation options, making them versatile and efficient for industrial flow control applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valves Category

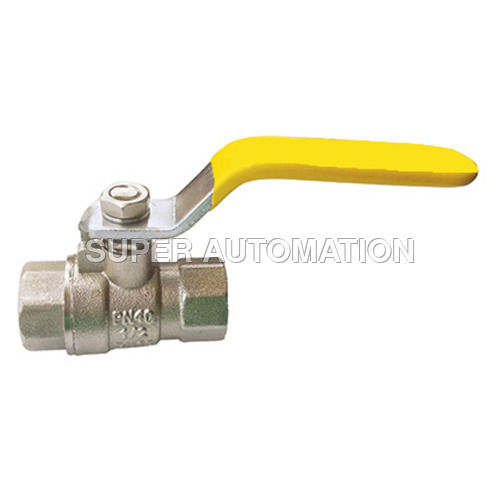

BRASS BALL VALVE

Price 500 INR / Piece

Minimum Order Quantity : 5 Pieces

Application : General Plumbing Water Flow Control

Valve Size : 1/2 inch 3/4 inch 1 inch etc.

Media : Other, Water Air Oil

Valve Type : Brass Ball Valve

3 Way Ball Valve

Price 280 INR / Piece

Minimum Order Quantity : as per requirement Piece

Application : Industrial, Water, Oil & Gas, Chemical Processing

Valve Size : 1/2 inch to 4 inch

Media : Other, Water, Oil, Gas, Chemicals

Valve Type : 3 Way

Stainless Steel Ball Valves

Application : Industrial, Water, Oil, Gas, Steam, Acid, Chemical Processing

Valve Size : 15mm to 150mm

Media : Other, Water, Oil, Gas, Steam, Chemicals

Valve Type : Full Bore / Reduced Bore

non return valve vertical

Application : Industrial, Water Line, Oil, Gas, Steam, Air, Chemical Industries

Valve Size : DN 15 DN 300

Media : Other, Water, Air, Oil, Gas, Steam

Valve Type : Non Return Valve (NRV)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry