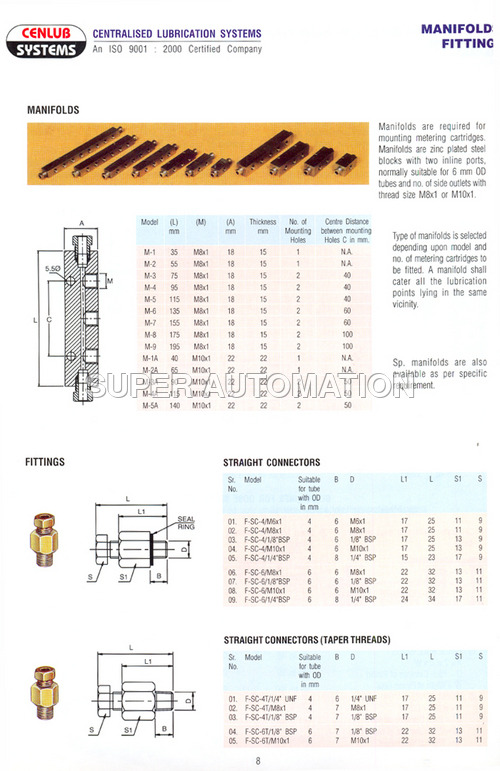

Aluminum Manifold Fittings

Aluminum Manifold Fittings Specification

- Automatic Grade

- Manual

- Usage & Applications

- Air, pneumatic, hydraulic distribution systems, machine connections, compressors, automation lines

- Size

- 1/4 inch to 1/2 inch BSP (custom sizes available)

- Type

- Aluminum Manifold Fittings

- Grade

- Industrial Grade

- Capacity

- Handles up to 10 Bar (145 psi)

- Dimension (L*W*H)

- Varies by model (commonly 100mm x 40mm x 35mm)

- Noise Level

- Silent/None

- Pressure Rating

- Max 10 bar (145 psi)

- Mounting Type

- Surface/Panel Mount

- Port Connection Type

- Threaded (BSP/NPT)

- Customization

- Available on request

- Corrosion Resistance

- Yes

- Finish

- Anodized/Sandblasted for corrosion resistance

- Packaging Type

- Individual Polybag or Box

About Aluminum Manifold Fittings

Since inception, our company has been catering to the variegated requirements of different domestic and global markets by manufacturing, supplying and exporting a wide range of Aluminum Manifold Fittings. These fittings are manufactured using high-quality aluminum and other basic metals incorporating sophisticated technology. We conduct different quality tests on these fittings to ensure their flawlessness. Offered Aluminum Manifold Fittings are available in different sizes and other specifications so that clients can avail from us as per their diversified requirements.

Salient features:

- High tensile strength

- Optimum resistance against corrosion

- Fine finish

- Dimensional accuracy

Superior Corrosion Resistance

Aluminum Manifold Fittings are treated with anodized or sandblasted finishes, effectively enhancing their resilience against corrosion. This ensures long-lasting performance in industrial applications where exposure to moisture or aggressive environments is common. These coatings help maintain reliable operation and appearance over time.

Customizable and Versatile

Catering to varied industrial requirements, these manifold fittings are available in standard and custom sizes, with options for surface or panel mounting. Whether you need specific dimensions or different port connection types, customization is provided on request, offering tailored solutions for your specific distribution system needs.

Reliable Performance for Industrial Grade Usage

Designed to meet industrial standards, these manifold fittings can handle a pressure rating of up to 10 bar (145 psi). Their silent, manual operation makes them suitable for air, pneumatic, and hydraulic systems, including compressors and automation lines, ensuring dependable performance and safety in demanding environments.

FAQs of Aluminum Manifold Fittings:

Q: How are Aluminum Manifold Fittings installed in air and hydraulic distribution systems?

A: Aluminum Manifold Fittings can be mounted either on surfaces or panels, using their threaded BSP/NPT port connections. Installation typically involves securing the fitting to the specified location and connecting the pipes or tubes according to the required flow configuration.Q: What benefits does anodized or sandblasted finishing provide for these fittings?

A: Anodized or sandblasted finishes enhance corrosion resistance, protecting the aluminum from environmental factors like moisture and chemicals. This extends the service life and reliability of the fittings, especially in harsh industrial conditions.Q: When is customization of manifold fitting size or port connection advisable?

A: Customization is suitable when your application requires non-standard dimensions or specific port thread types not covered by standard BSP/NPT options. Manufacturers accommodate such requests to fit unique system requirements and ensure optimal performance.Q: Where can these Aluminum Manifold Fittings be applied?

A: These fittings are widely used in air, pneumatic, and hydraulic distribution systems, as well as in machine connections, compressors, automation lines, and similar industrial setups. Their robust design suits both indoor and outdoor environments in factories and workshops.Q: What is the process for requesting a customized Aluminum Manifold Fitting?

A: To request a custom manifold fitting, provide your specificationssuch as required size, port connection type, and mounting preferenceto the manufacturer or supplier. They will review the application and suggest tailored solutions based on your needs.Q: How does the silent operation of these fittings benefit industrial environments?

A: Silent or noise-free operation contributes to a quieter workplace, improving employee comfort and supporting compliance with industrial noise standards. This feature is especially beneficial in automation lines and compressor systems.Q: Why should I choose Aluminum Manifold Fittings for my industrial setup?

A: These manifold fittings offer a combination of industrial-grade durability, corrosion resistance, customizable sizing, high pressure handling, and reliable manual operationmaking them a practical choice for distribution systems in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centralised Lubrication System Category

Centralized Lubrication Systems

Type : Other, Centralized Lubrication System

Noise Level : Less than 70 dB

Usage & Applications : Lubrication for machines in industrial automation, CNC, presses, and other industrial equipment.

Size : Standard/Custom

Grade : Industrial

Dimension (L*W*H) : 470 mm x 350 mm x 410 mm

Centralised Oil Lubrication

Type : Other, Centralised Oil Lubrication

Noise Level : Below 75 dB

Usage & Applications : Machinery and Industrial Equipment Lubrication

Size : Standard

Grade : Industrial

Dimension (L*W*H) : 450 x 250 x 350 mm

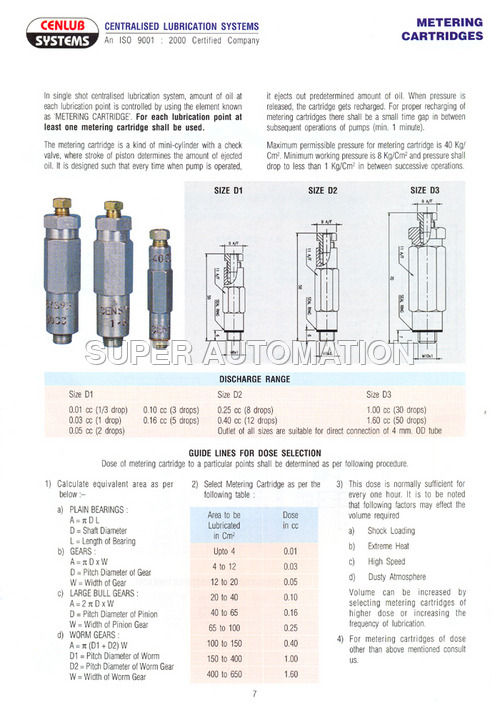

Lubrication Metering Cartridges

Type : Other, Lubrication Metering Cartridge

Noise Level : Silent operation

Usage & Applications : Used for accurate grease/oil dispensing in machinery, bearings, chain lubrication systems, and other industrial lubrication points

Size : Fits standard lubrication fittings

Grade : Industrial

Dimension (L*W*H) : Approx. 80mm x 26mm x 26mm

Oil Level Indicator Filters

Type : Other, Oil Level Indicator Filters

Noise Level : Silent/None

Usage & Applications : Hydraulic systems, gear boxes, and oil reservoirs for oil level indication and filtration

Size : 1/4 inch to 1 inch

Grade : Industrial

Dimension (L*W*H) : Variable (customized as per requirement)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry