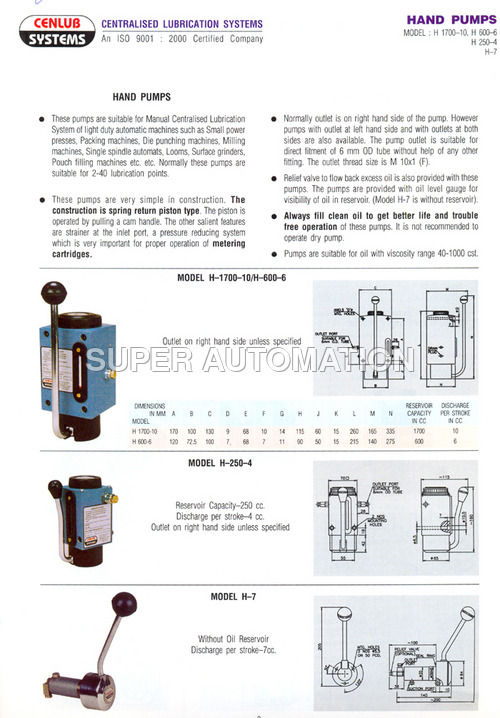

Centralized Lubrication Systems

Centralized Lubrication Systems Specification

- Filter Type

- Inbuilt oil filter

- Automatic Grade

- Automatic

- Size

- Standard/Custom

- Material

- Mild Steel (MS)/Metal

- Usage & Applications

- Lubrication for machines in industrial automation, CNC, presses, and other industrial equipment.

- Capacity

- Up to 10 liters

- Type

- Centralized Lubrication System

- Grade

- Industrial

- Dimension (L*W*H)

- 470 mm x 350 mm x 410 mm

- Noise Level

- Less than 70 dB

- Power

- 0.18 kW

- Voltage

- 220 V AC

- Control Panel

- Integrated with timer and level indicator

- Level Sensor

- Low oil level switch included

- Protection Class

- IP54

- Standards

- ISI/ISO Compliant

- Pump Type

- Gear Pump/Electric Motor Driven

- Mounting

- Wall/Panel Mounted

- Outlet Connection

- 1/4" BSP

- Operating Temperature

- 0°C to 55°C

About Centralized Lubrication Systems

Driven by ethical business policies, our firm is engaged in manufacturing, supplying and exporting a broad range of Centralized Lubrication Systems. These systems are designed with qualitative components with the help of our well-trained professionals. Offered systems are widely used in automobile and other manufacturing industries for lubricating different types of objects or parts. Furthermore, we timely deliver these Centralized Lubrication Systems at the premises of our patrons to ensure obtain their optimum satisfaction.

Salient features:

- High efficiency

- Low maintenance

- Prolonged functional life

- User-friendly operations

Reliable Automated Lubrication

This system ensures continuous and precise delivery of oil to machinery, reducing manual intervention and minimizing wear. The integrated electric gear pump delivers lubricant at required intervals, ensuring equipment stays protected. The smart control panel, complete with a timer and low-level sensor, guarantees efficient lubricant management and prevents system failures due to insufficient oil. Designed to streamline routine maintenance, it is perfect for demanding industrial applications.

Robust Construction for Industrial Environments

Constructed from high-quality mild steel, this lubrication system is built to withstand harsh industrial conditions. It carries an IP54 rating, protecting it against dust and water splashes, while the inbuilt oil filter maintains lubricant purity. The compact size and versatile mounting options allow convenient installation, even in spaces where accessibility is limited. Full ISO and ISI compliance ensures it meets stringent industry standards.

FAQs of Centralized Lubrication Systems:

Q: How does the centralized lubrication system function in industrial machinery?

A: The system automatically dispenses lubricant at programmed intervals using an electric gear pump operated by an integrated control panel with a timer. This consistent delivery reduces friction and wear, enhancing the lifespan and performance of industrial equipment.Q: What benefits does the integrated control panel with timer and level indicator provide?

A: The control panel automates lubrication scheduling and includes a low oil level alarm, ensuring machines always receive optimal lubrication. This reduces the risk of downtime and prevents damage caused by insufficient oil supply.Q: When should the lubrication system be used in an industrial setting?

A: It should be employed whenever critical machinerysuch as CNC machines, presses, or automated systemsrequires regular and precise lubrication. Its timer-based operation ensures all lubricated points receive oil according to specific maintenance schedules.Q: Where can the centralized lubrication system be installed?

A: Thanks to its wall or panel mounting design, the system can be installed near machinery in a range of industrial environments, including production lines, automation setups, and workshops, wherever centralized lubrication is needed.Q: What is the installation process for the lubrication system?

A: Installation involves securely mounting the unit on a wall or panel, connecting the 1/4" BSP outlet, integrating it into the machines lubrication points, and connecting to a 220 V AC power source. The built-in level sensor and timer can then be configured for automated operation.Q: What applications are best suited for this lubrication system?

A: It is ideal for use in industrial automation, CNC machinery, presses, and other industrial equipment where regular, accurate lubrication is essential for operational efficiency.Q: What are the key benefits of using a mild steel, IP54-rated lubrication system in industrial environments?

A: Mild steel ensures mechanical strength and durability, while the IP54 rating provides protection against dust and water. This combination makes the system reliable and long-lasting, even in demanding industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Centralised Lubrication System Category

Centralised Oil Lubrication

Size : Standard

Dimension (L*W*H) : 450 x 250 x 350 mm

Usage & Applications : Machinery and Industrial Equipment Lubrication

Grade : Industrial

Noise Level : Below 75 dB

Type : Other, Centralised Oil Lubrication

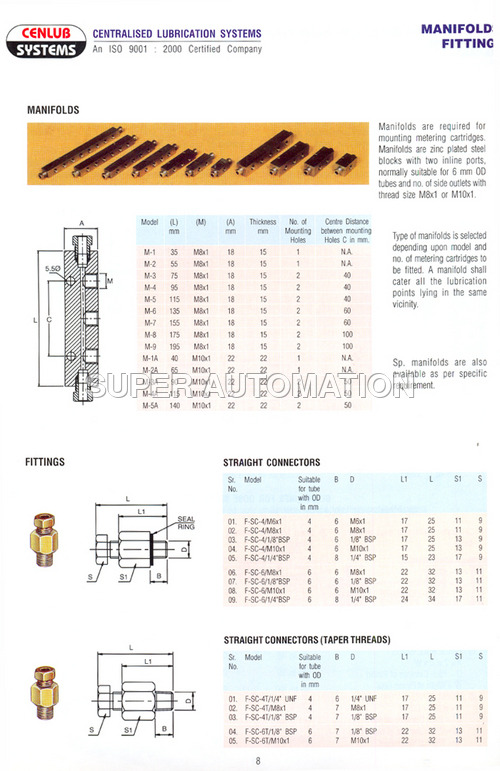

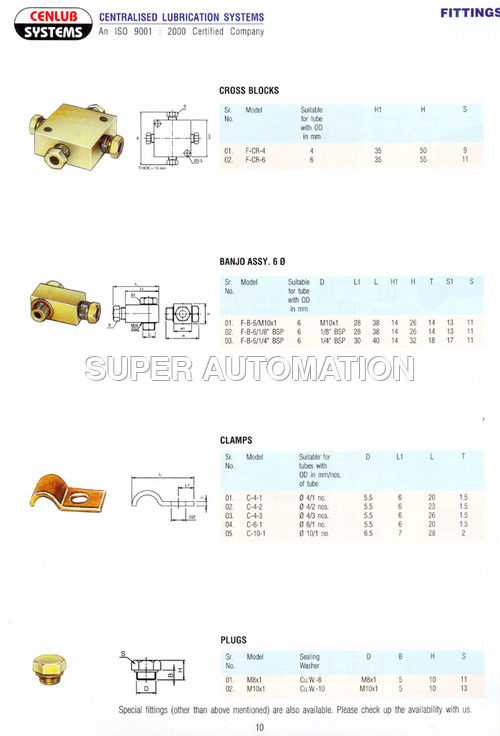

Aluminum Manifold Fittings

Size : 1/4 inch to 1/2 inch BSP (custom sizes available)

Dimension (L*W*H) : Varies by model (commonly 100mm x 40mm x 35mm)

Usage & Applications : Air, pneumatic, hydraulic distribution systems, machine connections, compressors, automation lines

Grade : Industrial Grade

Noise Level : Silent/None

Type : Other, Aluminum Manifold Fittings

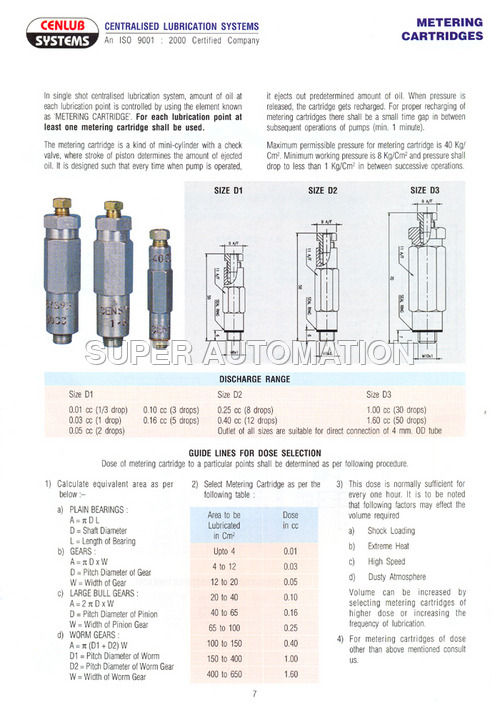

Lubrication Metering Cartridges

Size : Fits standard lubrication fittings

Dimension (L*W*H) : Approx. 80mm x 26mm x 26mm

Usage & Applications : Used for accurate grease/oil dispensing in machinery, bearings, chain lubrication systems, and other industrial lubrication points

Grade : Industrial

Noise Level : Silent operation

Type : Other, Lubrication Metering Cartridge

Oil Level Indicator Filters

Size : 1/4 inch to 1 inch

Dimension (L*W*H) : Variable (customized as per requirement)

Usage & Applications : Hydraulic systems, gear boxes, and oil reservoirs for oil level indication and filtration

Grade : Industrial

Noise Level : Silent/None

Type : Other, Oil Level Indicator Filters

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry