non return valve flange end

non return valve flange end Specification

- Control System

- Manual

- Valve Type

- Flanged end swing check valve

- Connection Type

- Flanged end

- Valve Size

- DN25 to DN600

- Material

- Cast iron / Ductile iron / Stainless steel

- Sealing

- EPDM / NBR / PTFE

- Structure

- Swing type, single plate

- Application

- Water, oil, gas, steam, and general industrial fluid flow control

- Pressure

- PN10, PN16, class 150

- Media

- Liquid, gas, steam

- Port Size

- Varies (25mm to 600mm)

- Disc

- Stainless steel / Cast iron / Ductile iron

- Installation Position

- Horizontal or vertical (upward flow)

- Color

- Blue or as customized

- Design Standard

- BS 1868 / API 6D / EN 12334

- Operation

- Automatically opens in forward flow and closes on reverse flow

- Flange Standard

- DIN PN10/PN16, ANSI 150

- End Connection

- Flanged drilled as per standards

- Coating

- Fusion bonded epoxy or as specified

- Body Coating Thickness

- Min. 250 microns

- Face to Face Dimension

- Conforms to DIN EN 558, ISO 5752

- Body Test Pressure

- 1.5 × rated pressure

- Application Industry

- Water Treatment, HVAC, Firefighting, Industrial Processing, Irrigation

- Seat Test Pressure

- 1.1 × rated pressure

About non return valve flange end

Featured for its preeminent quality and impeccable engineering, our Flanged End Non Return Valves offer a majestic solution for fluid flow control. Capitalise on advanced designface to face dimension conforms to DIN EN 558/ISO 5752 and flange standards DIN PN10/PN16, ANSI 150. Coated with a minimum 250 micron fusion-bonded epoxy, these valves are built for robust performance in water, oil, gas, steam, and other general industry applications. Automatic operation ensures reliability, while high-grade sealing and materials guarantee long-lasting service. Shop Now to benefit from trusted supply across India!

Preferred by Leading IndustriesUnmatched Quality & Versatility

This valve is widely used by water treatment plants, HVAC systems, fire protection networks, industrial processors, and irrigation setups. Its primary competitive advantages include robust construction, compatibility with numerous fluids (water, oil, gas, steam), varied port sizes (25mm to 600mm), and flexible installation both horizontally or vertically. Suitable for use in liquid, gas, and steam media, it ensures leak-proof control with EPDM, NBR, or PTFE sealingearning the trust of industry leaders nationwide.

Domestic Market Reach & Sample PolicyCustomer Convenience Guaranteed

We offer convenient exchange and prompt delivery throughout the domestic market. Our presence spans key industrial hubs, providing ready availability and rapid fulfillment. To help customers evaluate quality first-hand, we offer samples on request under a transparent sample policy. Each order, whether for distributors, suppliers, traders, or exporters, benefits from this assurancemaking our valves a reliable choice for Indias broad spectrum of fluid control applications.

Preferred by Leading IndustriesUnmatched Quality & Versatility

This valve is widely used by water treatment plants, HVAC systems, fire protection networks, industrial processors, and irrigation setups. Its primary competitive advantages include robust construction, compatibility with numerous fluids (water, oil, gas, steam), varied port sizes (25mm to 600mm), and flexible installation both horizontally or vertically. Suitable for use in liquid, gas, and steam media, it ensures leak-proof control with EPDM, NBR, or PTFE sealingearning the trust of industry leaders nationwide.

Domestic Market Reach & Sample PolicyCustomer Convenience Guaranteed

We offer convenient exchange and prompt delivery throughout the domestic market. Our presence spans key industrial hubs, providing ready availability and rapid fulfillment. To help customers evaluate quality first-hand, we offer samples on request under a transparent sample policy. Each order, whether for distributors, suppliers, traders, or exporters, benefits from this assurancemaking our valves a reliable choice for Indias broad spectrum of fluid control applications.

FAQs of non return valve flange end:

Q: How does the non return valve flange end operate?

A: The non return valve automatically opens with forward flow and closes on reverse flow, preventing backflow and ensuring unidirectional movement.Q: What industries benefit from using this valve?

A: This valve is ideal for water treatment, HVAC, firefighting, industrial processing, and irrigation. Its robust design suits a wide range of fluid control needs.Q: When should I choose a valve with fusion bonded epoxy coating?

A: Fusion bonded epoxy coating is recommended when you require enhanced durability and corrosion resistanceparticularly in water, steam, or chemical fluid environments.Q: Where can this swing check valve be installed?

A: The valve can be installed in either horizontal pipelines or vertical lines with upward flow, offering flexible integration into various systems.Q: What is the process for obtaining a sample before placing a full order?

A: You can request a sample through our standard sample policy. Contact our sales team, and we will assist you with the sample offer and subsequent order process.Q: What are the main advantages of the valves flanged end connection?

A: Flanged end connection provides easy installation, secure fitting, and compatibility with standard pipeline flanges, enhancing reliability and simplifying maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Valves Category

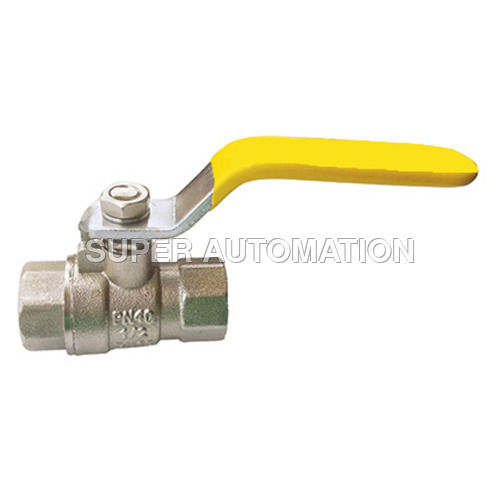

BRASS BALL VALVE

Price 500 INR / Piece

Minimum Order Quantity : 5 Pieces

Power : Other, Not Applicable (Manual Operation)

Pressure : Other, Moderate Pressure

Media : Other, Water Air Oil

Control System : Manual

actuator with buterfly valve

Power : Other, Pneumatic or electric actuator required

Pressure : Other, Up to 16 bar

Media : Other, Water, air, oil, gas, corrosive fluids

Control System : Remote/Manual/Automated options

Non Compensated Flow Control Valves

Power : Manual

Pressure : Other, Max 350 Bar

Media : Other, Oil, Air, Water (as compatible)

Control System : Manual Adjustment

Flanged Globe Valves

Power : Manual

Pressure : Other, PN16, PN25, PN40

Media : Other, Water, Oil, Gas, Steam

Control System : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry